Innovative Sealing Solutions for Enhanced Preservation and Convenience in Everyday Use

The Benefits of Machine Seal Cups A Modern Solution for Packaging

In today's fast-paced world, ensuring the freshness and quality of food and beverages is more crucial than ever. One innovative solution that has gained popularity in various industries is the machine seal cup. This packaging method offers numerous advantages over traditional sealing techniques, making it an essential choice for manufacturers, retailers, and consumers alike.

Machine seal cups are designed to create an airtight and leak-proof seal around the product, usually made from a combination of materials such as plastic, aluminum, and paperboard. The technology behind these seals involves using advanced machinery to apply heat and pressure to the sealing material, which ensures a secure bond. This process not only enhances the durability of the packaging but also significantly extends the shelf life of the contents inside.

One of the primary benefits of machine seal cups is their ability to preserve freshness. The airtight seal prevents air, moisture, and contaminants from entering, which can lead to spoilage. In sectors like food and beverage, this means that products can be stored for longer periods without losing their quality. For example, machine-sealed cups are increasingly used for dairy products, salads, and ready-to-eat meals, helping maintain their freshness from production to consumption.

Another advantage is the convenience offered by machine seal cups. The design allows for easy handling and transportation, making them ideal for both consumers and retailers. When products are securely sealed, they are less likely to be damaged in transit, reducing the likelihood of returns and waste. Additionally, many machine seal cups are designed for single-use, catering to the needs of busy consumers who prioritize convenience in their daily lives.

machine seal cup

Sustainability is also a significant consideration in today’s packaging industry, and machine seal cups can be designed with eco-friendly materials. Many manufacturers now offer recyclable or biodegradable options that help reduce waste and minimize environmental impact. By choosing machine seal cups made from sustainable materials, businesses can improve their eco-friendliness while still meeting the demands of consumers who are increasingly conscientious about their environmental footprint.

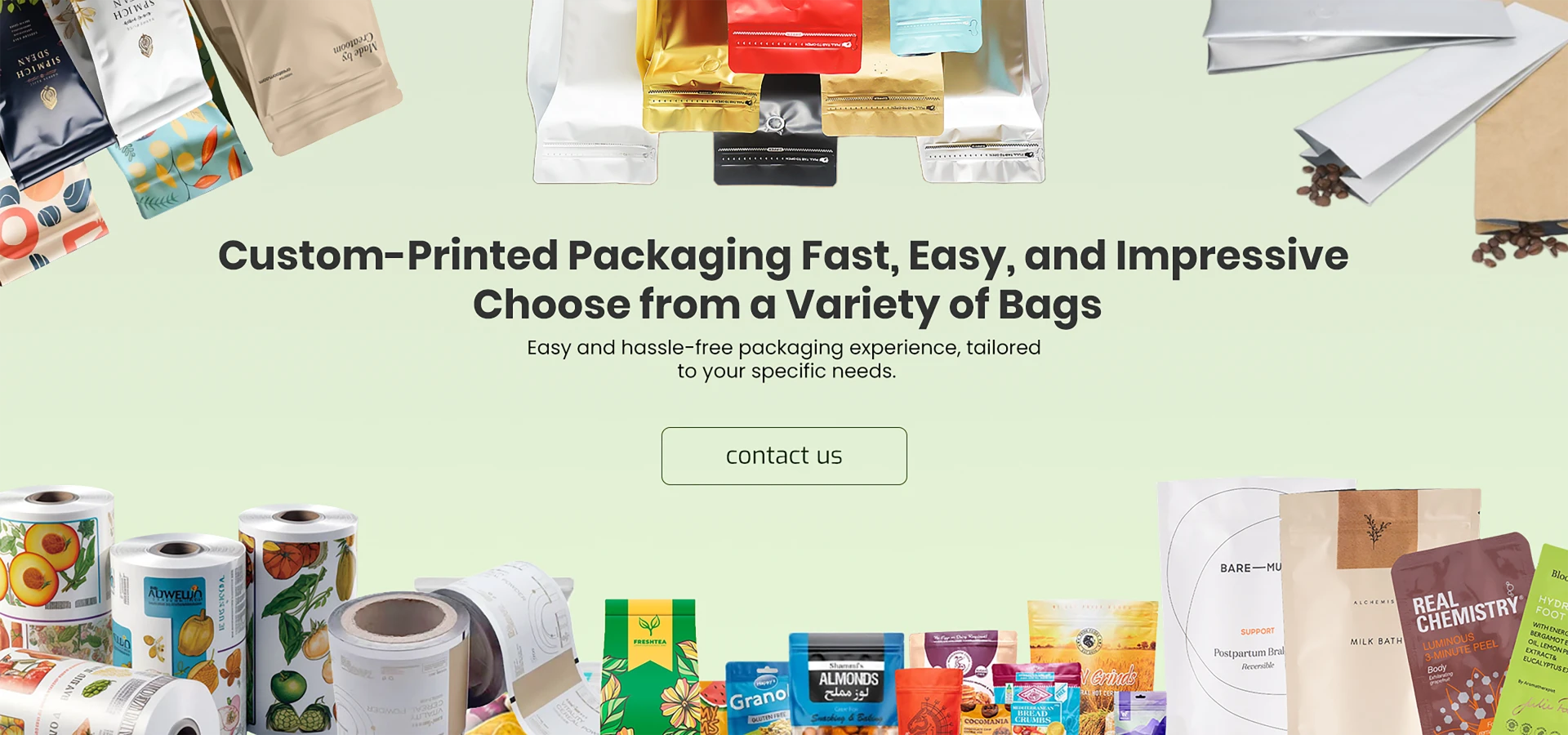

Furthermore, machine seal cups provide excellent branding opportunities for businesses. The surface of the cups can be customized with vibrant colors, attractive designs, and clear labeling, helping products stand out on the shelf. Effective branding is crucial for attracting consumers' attention, and the ability to package products in visually appealing ways can make a significant difference in a competitive market.

From a cost perspective, machine sealing can be an economical choice for manufacturers. Although the initial investment in sealing machinery may be substantial, the long-term savings achieved through extended shelf life and reduced waste can outweigh these costs. Additionally, the enhanced efficiency and speed of the sealing process allow businesses to increase their production rates, further contributing to cost savings.

In conclusion, machine seal cups represent a modern, efficient, and effective solution for packaging a wide range of products. With their ability to preserve freshness, offer convenience, promote sustainability, enhance branding, and reduce costs, they are becoming increasingly popular in industries such as food, beverages, cosmetics, and pharmaceuticals. As technology continues to advance, we can expect machine seal cups to evolve further, meeting the changing needs of consumers and businesses while driving innovation in the packaging sector. In a world that values quality, efficiency, and sustainability, machine seal cups are undoubtedly paving the way for the future of packaging.